|

|

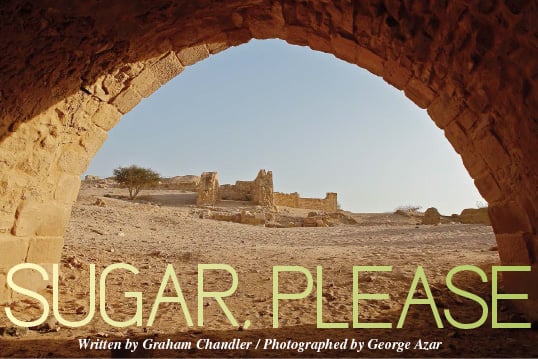

Entering Tawahin es-Sukkar, or "sugar millstone," the mill room lies straight ahead. Lower: Crushing sugar cane to extract its sweet juice is the first step of sugar refining, and this is still done at street shops throughout Jordan and other countries in the region, even though sugar cane has not been grown here for 500 years.

|

he month is October and it's only 9:30 in the morning, but already we're looking for shade. Under an azure sky

just south of the Dead Sea in Jordan, there's no hint of a breeze either. The only sound is a distant working

tractor and the odd buzzing fly.

he month is October and it's only 9:30 in the morning, but already we're looking for shade. Under an azure sky

just south of the Dead Sea in Jordan, there's no hint of a breeze either. The only sound is a distant working

tractor and the odd buzzing fly.

It wasn't always so quiet here. As I sit on a weathered stone grinding wheel the size of a tractor tire, my

imagination runs back a thousand years to when this place bustled with hundreds of workers cutting, hauling,

crushing, stoking, boiling, pouring—producing one of the planet's greatest life-changing foodstuffs: sugar.

Along with quinine, potato, cotton and tea, sugar cane has been called one of the five plants that transformed

humankind, and Tawahin es-Sukkar was a key location in its first mass production and global commercialization.

This place, along with several others on both sides of the River Jordan, had what sugar needed: fertile and

irrigated farmland, labor to harvest and cut the cane, water power to drive the stone wheels to crush it, fuel

to stoke the fires to boil it, minerals to clarify it, a ceramic industry to make the pots in which it crystallized

and trade networks to market it. But before all that could happen, sugar cane had to be adapted to grow in a climate

nature hadn't intended for it.

Probably even in its wild state, sugar attracted humans. "I think the desire for sweetness in humans does have

an evolutionary basis," says Sidney Mintz of Johns Hopkins University, author of the seminal 1985 book Sweetness

and Power: The Place of Sugar in Modern History. "We are primates, descended from arboreal fruit eaters," he says.

"Sweetness may have been a signal of edibility, its taste eventually incorporated into the hominid taste apparatus."

|

|

|

Above: Situated between the lowland fields that grew sugar cane and the highlands that provided water, Tawahin

es-Sukkar is the site of excavations that have unearthed walls, aqueducts and, bottom, water chutes whose height

lent power to the water that drove the millstone and then flowed out to irrigate fields.

|

Ten thousand years back, in what is now New Guinea, botanists believe, sugar was first cultivated, and it came to

enjoy the humid Melanesian environment. The taste of it caught on fast: Cane fields were soon sprouting in the

Philippines, Indonesia, China and India.

All of these societies had honey, but they found sugar cane was different—and more desirable. As it spread,

people learned to extract and process the sweet juice from its bamboo-like stems. Of the six known species of sugar

cane, it is Saccharum officinarum or "apothecaries' sugar" that has followed history to our tables. It grows up to

4½ meters (15') high and about five centimeters (2") around. Give it ample water and sunshine and you can almost

watch it grow—a couple of centimeters (¾") a day isn't unheard of.

|

Early processors, however, learned it was finicky. After taking a year to mature, sugar must be cut at its peak

and the juice crushed out within a day, or else it "inverts" (ferments). And the juice must be boiled promptly

and poured into pots. As the water content evaporates, the increasingly concentrated sucrose solution can be

left to cool. When it's supersaturated, it crystallizes and solidifies into the shape of its container, leaving

behind a part of itself that won't crystallize—known to us as molasses, or treacle. Along the way it has to

be clarified to be rid of impurities. These techniques became the specialty of the experts at Tawahin es-Sukkar.

Archeologist Richard Jones of the University of Glasgow and his team have chemically analyzed several samples

from the site and find direct evidence of sugar elusive. "The biggest puzzle is that we have the building, the

mill, the water channels, the thousands of sugar pots—but still we find it very hard to find even traces

of sugar cane" because, he explains, "any sugar-containing lump is usually eaten away by microbial action or

eventually dissolves away." However, a 2011 botanical analysis, part of the site's most recent excavations under

the direction of Konstantinos Politis of the Hellenic Society for Near Eastern Studies, has disclosed evidence of

actual sugar cane fragments for the first time, according to the society's Web site. Jones has also discovered

calcium-based materials that were used for clarification and has matched them with sediments from the nearby Lisan

peninsula of the Dead Sea.

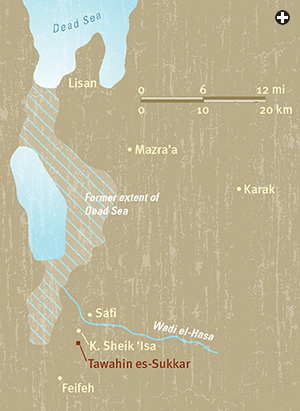

And that place likely supplied more sites than just Tawahin es-Sukkar, because this is just one of the largest

and best preserved of several dozen early sugar-production centers known along the Jordan Valley. Ruba AbuDalo

investigated 10 of them for her master's thesis at Jordan's Yarmouk University. "The Jordan Valley is the most

fertile region of Jordanian territories," she says. Numerous archeological remains connected to sugar have been

found all the way to the Mediterranean coast, and she has identified 34 sites in the Jordan Valley.

|

|

adapted from e. photos-jones, a. hall, r. jones, e. pantos / herring design |

"The mills were built on the sides of rivers or streams because sugar cane relied on an exploitable water supply

to operate the mills," she explains. The leading source of evidence of sugar processing at smaller sites are pots

shaped like inverted bells that she says historian Nuwayri, in 1332, called alabaleej, and that were used to drain

the sugar solution to the molasses level.

The basic reduction technique of sugar refining has been known for almost as long as the plant. Around 327 bce,

Alexander's general Nearchus, at the Indus River, wrote that "a reed in India brings forth honey without the

help of bees, from which an intoxicating drink is made, though the plant bears no fruit." Historians believe

northern India was sugar cane's first center of innovation.

"Sugar crystallized from the juice of sugar cane 2000 years or more ago was often marked by both medical and

religious overtones, as in India," says Mintz. "As such, it was commonly incorporated into life-crisis ceremonies."

The earliest known writings on sugar production come from around 500 ce in a Hindu

religious document known as the Buddhagosa, which describes a sequence of steps similar to those still known today.

Indeed the words sukkar in Arabic and sugar in English both derive from the Sanskrit sakara,

meaning "gravel," which at once evokes the granular result of sugar-cane processing.

By that same time, the Chinese, too, were growing sugar cane in their tropical regions. Eager to learn how to

process it, Emperor T'ai Tsung sent a mission to India in 647 to learn, and soon sugar was being used as a

preservative for shipping fruit and as a seasoning in Chinese cuisine. Indeed, the Indian influence was far-reaching:

Byzantine emperor Heraclius, on seizing one of the Persian king Chosroes ii's royal dwellings near Baghdad in

627, called the sugar he found an "Indian" luxury.

But just seven years later, Muslim armies defeated Heraclius, and with the Islamic conquests there and throughout

the Middle East and North Africa, there also came the Arab agricultural revolution. At the heart of it were crops

new to the Islamized regions, and one of them was sugar cane.

It was in Persia that the Arabs discovered the sweet plant, in the mid-600's, following the fall of the

Sassanid Empire. Sugar had probably come to the Sassanids by sea from India some time before that, because a

Chinese source from the late seventh century mentions Persian sugar, though without making clear whether it was

grown there or imported. Nonetheless, cane never really liked the hot, dry climes of Persia, so it was up to the

Arabs to figure out how to cultivate it in sufficient quantity to justify the extraordinary efforts it required

to process. Cropping patterns needed transforming, fertilizers needed developing and, importantly, irrigation

technology needed a revolution of its own: Growing sugar cane outside its native climate is a challenge.

|

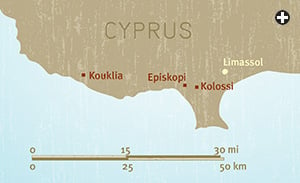

Throughout the eastern Mediterranean and Levant regions, sugar cane milling began with a millstone that was rolled

about on a circular base, powered by a horizontal, underground water wheel. Below to bottom: Tawahin es-Sukkar, Kouklia

and Kolossi, Cyprus.

|

|

|

|

According to J. H. Galloway, professor of geography at the University of Toronto and author of The Sugar Cane

Industry, the threshold low temperature for sugar's satisfactory growth is 21 degrees Centigrade (70°F). Below

that, growth slows, and at 13 degrees Centigrade (55°F) it stops. The plant thrives between 27°C (81°F) and 38°C

(100°F). Most importantly, cane needs copious amounts of water year-round.

Arab lands had been irrigated for millennia, but sugar cane was the first crop that was not seasonal. For most

crops, fields could lie fallow in the hot, dry summers. Not so sugar cane, which demanded that water be lifted

out of rivers during low-flow periods. Reports from Egypt show that irrigation was needed some 28 times between

annual Nile floods. This helped spur improvements to hydrological devices like the noria, or water wheel, and by

the 11th century, "there was hardly a river, stream, oasis, spring, known aquifer or predictable flood that went

unused," says Andrew Watson of the University of Toronto, author of Agricultural Innovation in the Early Islamic World.

New fertilizers were needed too. Watson pored over the dozen or so agricultural manuals that were produced across

the Arab world of the time. "The manuals recommended extensive use of all kinds of animal and green manures, as

well as urging plowing, digging, hoeing and harrowing," he says. Moreover, they made recommendations on sett spacing

and furrow depths, and how to store setts with a light soil covering—techniques still practiced today.

But more than water, fertilizer and tillage were required. Along with the diffusion of other contemporary crops such

as sorghum, cotton and coconut palm—all part of the Arab agricultural revolution—sugar's need for new

technology and new harvesting cycles spawned political and social changes as they spread from east to west. Irrigation

required capital.

Water rights and marketing demanded new laws to ensure dependability. And new tax regimes helped farmers using

irrigation-intensive techniques by requiring a mere five percent of their produce in taxes, in contrast to farmers

who used traditional gravity-irrigation: They had to pay fifty percent of their produce. New labor, too, which built,

operated and maintained the irrigation complexes, worked and harvested in the newly intensified fields. This led to

the introduction of sharecropping. "It is the singular contribution of the Arabs to have brought these conditions

about in the years following the birth of Islam," writes Galloway.

Watson contrasts the Arab agriculture with Europe's of the time. The Arabs' "economy was monetized and they produced

and traded extensively with one another," which enabled large-scale sugar production. But, I ask, what prompted them

to go to such lengths to produce sugar? "Money and profits, I suppose," he says. "It was quite unlike Europe at the

time, where people were self-sufficient, but there wasn't the same monetized trading economy."

All these changes effected new ways of living, or what today we might call lifestyles. Watson reckons the higher

income per unit of land, the availability of new land and the greater demands for labor all encouraged early

marriage and larger families and thus broad changes in population. Indeed, the historical record shows villages

popping up in newly farmed areas and becoming ever more numerous and populous. And cities grew, too, well fed by

the increasing food surpluses.

As part of this agricultural revolution, sugar cane wasn't restricted to the Jordan Valley. References to sugar-cane

cultivation appear throughout the Nile Valley and Delta, in Syria, Palestine and across North Africa, as well as in Spain,

Cyprus, Malta, Sicily and Crete. As Mintz puts it, sugar "followed the Qur'an." Neither historians nor archeologists, h

owever, have pinned down exactly when these industrial-scale sugar mills first appeared, for the record is sparse until

the 10th century.

In Europe, by around 1100 ce, sugar was categorized with spices like pepper, nutmeg, mace, ginger and

cardamom—exotic and pricey imports used sparingly, even by those who had the cash. Long before that,

sugar was both a medicine and a spice in the eastern Mediterranean and across North Africa. Physicians from India

to Spain had adopted it, and European doctors first learned uses of sugar through Arab pharmacology. The 11th-century

Arabic-language medical manual Qanun fi'l-Tibb, by the Persian scholar Ibn Sina (Avicenna), remained a European

authority until the late 1500's. "As a medicine, sugar figured prominently in the antidotes—all of them

bootless, of course—for the Black Plague," says Mintz. Other uses appear bizarre today: "One prominent

medieval medical use involved mixing the finest powdered white sugar with gold dust, then blowing the mixture

into the eyes of those afflicted with certain eye maladies," he says.

Medicine wasn't sugar's only use back then. Mintz writes of the 11th-century caliph al-Zahir, who celebrated feast

days with table-sized models of palaces built of sugar, and of an Egyptian ruler who in 1040 reportedly used more

than 73,000 kilograms (80 tons) of the stuff for a feast following Ramadan.

As such sweet decadence caught on with the European royal courts, it drove new and ever-more efficient production,

especially in the nearby lands of the Mediterranean. Eleventh-century Crusaders had noted this commercial sugar

boom in the Levant, where sugar was being refined at Tawahin es-Sukkar and elsewhere, and soon they themselves

in the thick of the commercial competition.

Nowhere is this more clearly to be seen today than in Cyprus, where remains of sugar production are the best

preserved and the most intensively investigated by archeologists. I'm standing beside the A6 highway between

Limassol and Paphos, on the rocky southwest coast of Cyprus, looking at a broken-down stone aqueduct cutting its

way through an orange grove. Seven centuries ago, it brought water from springs in the Oridhes forest to drive the

mills and water the fields at the sugar-producing site of Kouklia.

|

Kouklia's process paralleled that of Tawahin es-Sukkar. The water was channeled into a narrow sluice down a

steep incline into an underground vault, where a stone nozzle focused the stream onto a wooden water wheel.

You can stand straight in this huge room and see shoulder-high scrapes on its walls from the wheel that must

have been nearly five meters (16') across. In the far corner of the room there's a channel wide enough to walk

through where the water would flow off to irrigate the cane fields after doing its work at the wheel, which drove

a giant stone grinding wheel above.

This was large-scale industrialization of its era: Enough sweet juice was pressed out to keep eight massive

copper cauldrons boiling, and the brick-lined, fire-blackened hearths are still there to see. From the cauldrons,

the hot syrup was poured into three sizes of cone-shaped molds, broken shards of which still lie scattered about.

Eastward down the scenic coast road past Petra, near the vast antenna networks of the Royal Air Force base at

Akrotiri and more fields of orange and grapefruit, lie two more, similar early sugar production sites—Episkopi and Kolossi.

Slim and chic in designer denims and swept-back salt-and-pepper hair, Marina Solomidou-Ieronymidou's piercing

brown eyes light up when she reveals her enthusiasm for these sugar sites she has excavated over a 17-year

stretch. Curator of antiquities at the Cyprus Museum, just outside the Paphos Gate of the old walled city of

Nicosia, she says she'd love to be back out there in the field. "There's so much more to do, more puzzles to

get into," she says.

At their production peak in the late 1400's, she explains, these were efficient commercial sites. "At Episkopi,

the Italian traveler Pietro di Casola in 1494 saw 400 workers there," she says. "There must have been an equal

number at Kolossi." Those teams were prodigious. "In 1532 the total production of sugar in Cyprus was 3000

quintals," she says—30,000 kilograms, or 33 tons.

|

Save for their implied scale of operation, these Cypriot sites are remarkably similar to Tawahin es-Sukkar,

demonstrating much of the same technology: The channeling of water through a nozzle driving an underground,

horizontal water wheel that drove an above-ground grinding wheel; liquid collection methods; boiling facilities;

shards of similarly shaped sugar pots. But historians aren't yet sure where that system was first constructed.

Startup dates for sites in the Levant haven't been as conclusively determined as for the Cyprus sites, but

Solomidou-Ieronymidou reckons the technology originated in the Levant and traveled west. "As the invention of

sugar production started in the Levant, I suppose the horizontal water wheel system originates also from that

area," she says. "It advanced in Cyprus through the Crusaders when they settled on the island in the late 12th century."

She tells me the majority of the sugar from Cyprus was exported to Venice, and that the well-to-do Cornaro

family was a major owner of Cypriot production. With production well under way, by the early 1200's more and

more sugar was finding its way into continental Europe. By the early 1300's, the British were some of the first

to get hooked. But at two shillings a pound—or about $78 in today's money—using sugar showed you could

afford it. So consumption remained largely restricted to royal courts and nobility, much of it carried out with

ostentatious swagger. As among the Arabs, elaborate sculptures were created for social events—so much that

Marie-Antoine Carême, an 18th-century French chef, once declared sugar sculpting the primary branch of architecture.

Dinner guests were regaled with spectacular confectionery renderings of entire castles, people, flowers and animals,

all of which they ate. But for the working classes, the first English cookbooks recommended sugar be used in the

older ways, as a spice, not a sweetener, in small amounts for meat, fish and vegetable dishes along with ginger,

saffron and cinnamon.

What kept sugar prices lofty was that, unlike the Levant, Cyprus and other Mediterranean lands were actually

marginal places for cane. Even with irrigation and adherence to the Arab manuals, the cooler winters and occasional

frosts meant the sugar cane here was less mature at harvest, and hence lower in sugar content. Moreover, by the

time of the Arab conquests, much Mediterranean forest had been over-exploited by other energy-hungry industries

like shipbuilding, metallurgy, pottery and glass, resulting in a scarcity of fuel for boiling sugar vats. Bagasse—

the residue of the cane after milling—wasn't employed as a fuel until later in tropical America.

And during the 14th and 15th centuries, as war and plague decimated agricultural labor, Mediterranean island estates

put more slaves to work—mostly prisoners of war from Greece, Bulgaria, Turkey and the Tatar coasts of the Black

Sea. Galloway writes that "the link between sugar production and slavery, which was to last until the 19th century,

became firmly forged in Crete, Cyprus and Morocco."

|

|

|

Cypriot sugar mills at Kouklia, top and Kolossi, bottom, were laid out similarly because of the technology of the refining

process: milling, boiling, molding and separating. Other areas served as stockrooms, workshops and fuel supply areas.

One contemporary account estimated the number of workers in a large sugar mill at more than 400.

|

These problems drove production westward, first to the near-Atlantic Madeira Islands, Canary Islands and Azores.

By the mid-1400's, Madeira was Europe's leading sugar supplier. Columbus, on his second voyage to the New World in

1493, picked up some cane plants in the Canary Islands and planted them on the island he called Hispaniola.

It was an instant success, as sugar cane there found heat, humidity and rainfall much like its indigenous New Guinea.

By 1516, the first commercial sugar shipments were on their way to Europe. Production costs in the Caribbean were low

compared to the Levant and the Mediterranean, as there was no need for irrigation and fuel was abundant. It was the

death knell for Old World sugar production.

The only resource in short supply was labor. The Caribbean islands' indigenous Taino were in rapid decline from European

diseases and persecution. So it was African slaves, who were already being imported for work in mines, who were forced

to toil on the sugar plantations. By the 1530's, Santo Domingo counted 34 mills and 200 slave plantations.

Sugar bloomed similarly on islands like Jamaica, Puerto Rico and Cuba, and Brazil's growth took off thanks to Portuguese

experience from Madeira and the Azores. By 1710, there were 528 plantations in Brazil. But it was England, writes Mintz,

that fought the most, conquered the most, imported the most slaves and went furthest and fastest in creating a New World

plantation system for sugar production.

In fact, it was in the 17th and 18th centuries that sugar became part of the English character, part of the "essence

of Britishness." In 1660, England consumed 1000 hogsheads of sugar and exported 2000. Forty years later, imports

were 100,000 hogsheads and exports 18,000; by 1753, exports had dropped to just 6000. (One hogshead is about 240

liters, or 63 gallons.) To support this growth, more than a quarter million slaves were landed in Barbados between

1701 and 1810, and 662,400 in Jamaica alone. Sugar had become the biggest single engine of the slave "triangular

trade" that linked Britain and Africa to the New World: European cloth, firearms, gunpowder and alcohol were shipped

to West Africa to pay for the purchase of slaves, who were sent in chains to the West Indies and sold at the quayside,

where the same ships loaded sugar, rum and molasses for the trip back home. The resulting lower prices made sugar

popular across the social spectrum, and new tastes developed. Sugar improved chocolate, as well as coffee and tea.

These drinks had long been thought bitter by Europeans, but it was cheap sugar that by the late 17th century enabled

chocolate drinking, coffeehouses and the custom of afternoon tea to trickle down to the middle classes.

|

To Mintz, there are yet more connections. "The decisions to sweeten them remain largely hidden from us still,"

he muses. "All three beverages are bitter, yet none were drunk sweetened in their places of origin." Tea and

coffee contain caffeine, and chocolate, too, is a mild stimulant. All became popular in an era of growing industrialization,

he points out, when long factory hours, urban life and the lack of a cow were all among the new experiences encountered

by proletarian families. "The first pause that refreshed antedated the cola drinks by centuries," Mintz says. Sugar

became common in porridge, breads and desserts, and it began to be associated with the milestones of British lives,

especially weddings, birthdays and funerals.

But increasingly, all that sugar was taken with more than a few lumps of guilt. That the ratio of slaves employed

to sugar produced was 10 times that of other plantation crops like tobacco or cotton, and that three-quarters of

all slaves out of Africa were destined for sugar plantations, all made sugar less sweet to the popular palate. A

member of parliament reportedly described Jamaica as "a place of great wealth, a den of tyrants, and a dungeon of slaves."

A turning point came in 1801. Britain and France were at war, and France, tired of running the Royal Navy's gauntlet

back to Europe, needed a closer source of sugar. That year, the first successful beet sugar production began in France.

Chemically identical to cane sugar, beet sugar within 15 years threatened the tropical-sugar trade and by 1830 supplied

more than half of the continental market. By 1880 it had overtaken cane in world trade.

Though Britain abolished slavery in 1834, and Cuba and the United States did so in 1865, the sugar-producing lands

of the New World were left without schools, major roads, water supplies, sewage and other critical infrastructures.

Newly freed slaves had no other place to go and few new sources of livelihood. As Mintz writes, "Sugar—or rather,

the great commodity market which arose demanding it—has been one of the massive demographic forces in world history."

Cane sugar could never have been what it was without Tawahin es-Sukkar and its progeny in the Levant and Mediterranean.

The importance of this role is such that the new Jordan Museum, under construction in Amman, has chosen Tawahin es-Sukkar

as one of its key permanent diorama exhibits.

"The Ayyubid-Mamluk period is generally connected with war and the Crusades," says the museum's former director general,

Faris Nimry. "It is important to show the other face." Tawahin es-Sukkar was picked, he says, because "the sugar

industry was a major part of Jordan's economy at the time, and it reveals several aspects of that. They were the first

large-scale organized sugar plantations known." It also demonstrates the political capacity for the administration of

such a large-scale industry, as well as economic and social impacts, he adds.

Today, sugar is mostly under attack again, accused of enabling if not causing global overindulgence in that peculiarly

modern food group, the "junk foods." But not everyone agrees. In Amman, just east of the imposing Arab Bank, past the

gold shops on Al-Malek Faisal Street, in a tiny shop—a stall, really—an operator feeds raw-cut sugar cane

stalks into an electric crusher while hawking glasses filled with fresh cane juice. His sign proclaims it "enhances

virility, improves eyesight and digestion and strengthens body and mind." At half a dinar, that seems like a sweet bargain.

|

Free-lance writer Graham Chandler (www.grahamchandler.ca)

focuses on topics in archeology, aviation and energy. He received his doctorate in archeology from the University

of London and lives in Calgary, Alberta.

|

|

Photojournalist and filmmaker George Azar (george_azar@me.com)

has covered the Middle East since 1981. He is the author of the books Palestine: A Photographic Journey

(University of California Press, 1991) and Palestine, A Guide (Interlink, 2006) as well as director of the

film "Gaza Fixer" (2007). |